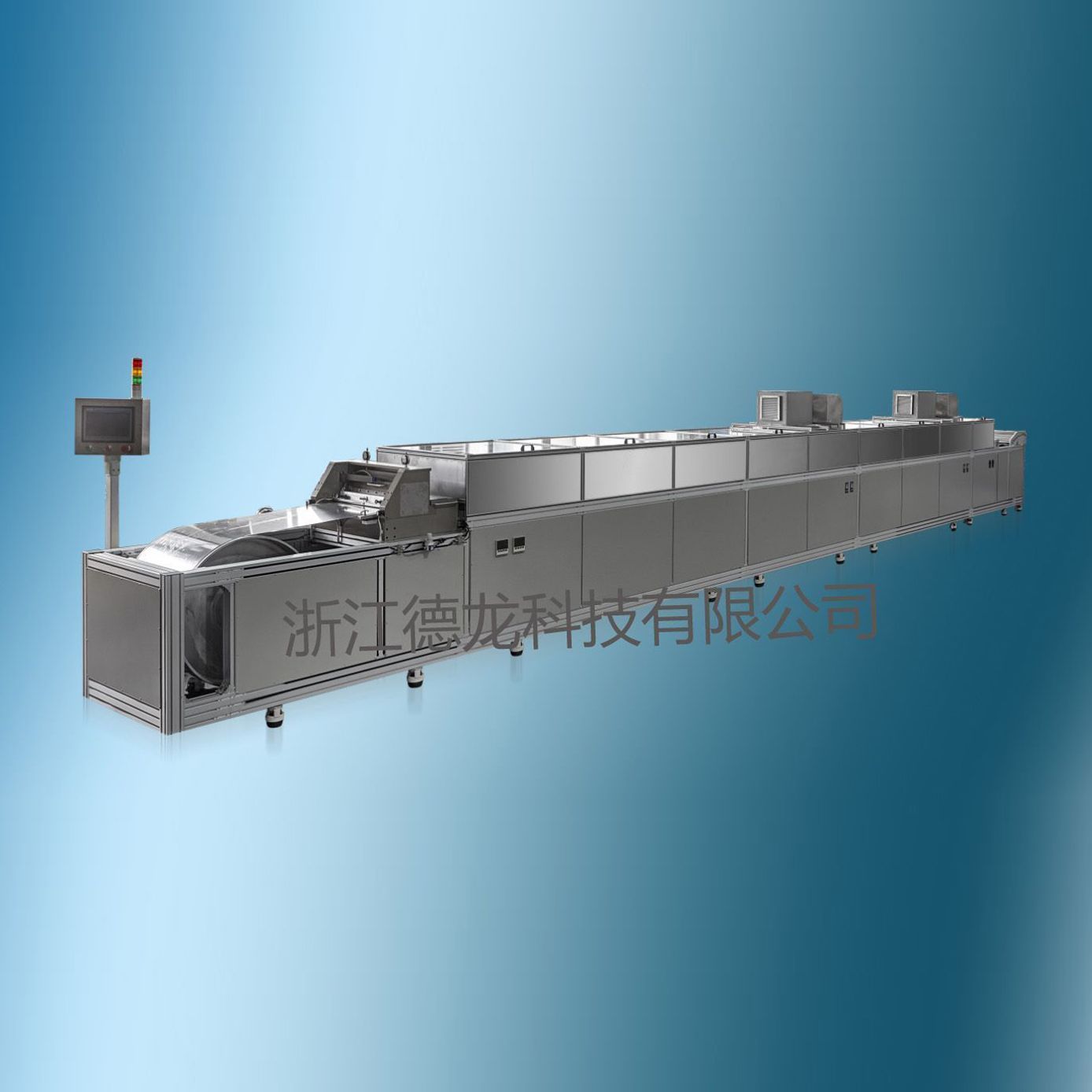

GD550 steel belt casting machine

- product description

Product Brief

u DR-LYJ-GD550 steel belt casting machine is to feed the mixed slurry into the material box after defoaming, and then pass the scraper blade to a certain thickness of the steel belt, after drying in the air duct area, and then enter the sink through the conveyor belt . It has high casting precision and high efficiency. From the feeding control, casting, air drying, forming, precipitation, transmission and other automatic control, the configuration is rich and the function is complete.

technical parameter1. The external dimensions (length*width*height) are 12000mm*1200mm*1600mm;

2. Steel belt (imported from the United States), length 23727mm*600mm*0.6mm wide;

3. Running speed of steel belt: 0.05--10m/min;

4. The motor power is 1.5KW servo motor + 1:100 precision reducer, the operation must be stable;

5. The running speed of the motor is displayed on a 10-inch touch screen digital display, which can be adjusted;

6. The steel belt runs smoothly, using a servo motor with a precision planetary reducer and an internal steel wire synchronous belt;

7. The diameter of the two tensioning wheels is 750mm, the surface is hard chrome plated, and the sink is designed under the rear steel rod;

8.Adjusted by cylinder diameter 125, adjustable tension, up to 1200Kg

9. The steel belt is equipped with a dust removal mechanism up and down to ensure that the surface of the conveyor belt is clean (spray device);

10. Designed with adjustment device to ensure that the axis of the two rollers is not parallel and less than 0.2

11. The width of the casting die is 550mm, the width of the die is designed in the box, and the two-sided baffle can be adjusted at will;

12. The casting box is equipped with a heating device (temperature 60-80 degrees), numerical control display; built-in heating rod, Japan Island Electric PID adjustment and display, control accuracy ±0.1℃

13. Casting-forming section, glass support at the bottom of the steel belt, the supporting mechanism adjusts the level in sections, one meter section, flatness is less than 0.1;

14. The surface flatness of the steel strip after stretching is plus or minus 0.02;

15. Casting-the forming section must have air ducts, and the air flow is 500m3/H;

16. Forming, precipitation section air flow 500m3/H, uniform wind speed;

17. In the precipitation stage, the support plate is designed with oblique mouth + water hole, in addition, the bottom of the steel belt is provided with a U-shaped groove for connecting the precipitated solution, and the bottom of the U-shaped groove is connected with a drainage pipe

18. Over transmission device of steel rod

19. Casting-waste gas recovery interface in the forming section, the diameter of the waste outlet is 150MM;

20. When the steel belt is running, the left-right deviation is less than 1.5, with a deviation adjustment device;

21. Knife adjustment method: inclined copper block + guide rail adjustment, adjustment gap (WET): 20~5000μm (scraper) accuracy ±1um

22. Air-drying area: gas nozzle + solution precipitation recovery device

23. Bellows length: 8 meters, the whole machine is 12 meters

24. Feeding method: Compressed nitrogen feeds the slurry into the feed box. The feed flow adjustment adopts a motor with ball screw and guide rail fitting structure. The feed flow is adjusted with high precision. After use, there is no need to clean the equipment. Replace 1 Pipeline is enough;

25. Power and distribution: bottom plate heating 300 width, power 4.2KW, servo motor power: 1.5KWW fan: 250W total power: 6.5KW

FeaturesØ 10 inch color touch screen, man-machine friendly interface. Using Siemens PLC control, stable performance, high precision, in line with industrial automation control standards;

Ø Exhaust air circulation system, uniform exhaust, variable frequency speed control of flow;

Ø High precision scraper, digital dial indicator display, resolution um;

Ø Adopt high-precision servo motor to control the speed of the steel belt, and the speed range can reach 0.05-10M/min;

Ø Automatic liquid level control, PID automatic adjustment, precision control ±0.5mm;

Unique and convenient process1. The air intake adopts high-density filter to achieve dust-free space;

2. Transparent tempered glass window, convenient to watch the internal casting status;

3. The thickened aluminum alloy is used for the internal materials of the spray-painted accessories to ensure the practical life of the accessories;

4. The whole machine adopts high-strength aluminum alloy frame, and the panel uses 2mm aluminum alloy plate, which is durable and beautiful.

Main configuration

1. Casting head 1 set

2. Cleaning device 1 set

3. Bellows 8 meters

4. Conveyor belt 1 group

5. Automatic feeding 1 set

Product Brief

u DR-LYJ-GD550 steel belt casting machine is to feed the mixed slurry into the material box after defoaming, and then pass the scraper blade to a certain thickness of the steel belt, after drying in the air duct area, and then enter the sink through the conveyor belt . It has high casting precision and high efficiency. From the feeding control, casting, air drying, forming, precipitation, transmission and other automatic control, the configuration is rich and the function is complete.

technical parameter1. The external dimensions (length*width*height) are 12000mm*1200mm*1600mm;

2. Steel belt (imported from the United States), length 23727mm*600mm*0.6mm wide;

3. Running speed of steel belt: 0.05--10m/min;

4. The motor power is 1.5KW servo motor + 1:100 precision reducer, the operation must be stable;

5. The running speed of the motor is displayed on a 10-inch touch screen digital display, which can be adjusted;

6. The steel belt runs smoothly, using a servo motor with a precision planetary reducer and an internal steel wire synchronous belt;

7. The diameter of the two tensioning wheels is 750mm, the surface is hard chrome plated, and the sink is designed under the rear steel rod;

8.Adjusted by cylinder diameter 125, adjustable tension, up to 1200Kg

9. The steel belt is equipped with a dust removal mechanism up and down to ensure that the surface of the conveyor belt is clean (spray device);

10. Designed with adjustment device to ensure that the axis of the two rollers is not parallel and less than 0.2

11. The width of the casting die is 550mm, the width of the die is designed in the box, and the two-sided baffle can be adjusted at will;

12. The casting box is equipped with a heating device (temperature 60-80 degrees), numerical control display; built-in heating rod, Japan Island Electric PID adjustment and display, control accuracy ±0.1℃

13. Casting-forming section, glass support at the bottom of the steel belt, the supporting mechanism adjusts the level in sections, one meter section, flatness is less than 0.1;

14. The surface flatness of the steel strip after stretching is plus or minus 0.02;

15. Casting-the forming section must have air ducts, and the air flow is 500m3/H;

16. Forming, precipitation section air flow 500m3/H, uniform wind speed;

17. In the precipitation stage, the support plate is designed with oblique mouth + water hole, in addition, the bottom of the steel belt is provided with a U-shaped groove for connecting the precipitated solution, and the bottom of the U-shaped groove is connected with a drainage pipe

18. Over transmission device of steel rod

19. Casting-waste gas recovery interface in the forming section, the diameter of the waste outlet is 150MM;

20. When the steel belt is running, the left-right deviation is less than 1.5, with a deviation adjustment device;

21. Knife adjustment method: inclined copper block + guide rail adjustment, adjustment gap (WET): 20~5000μm (scraper) accuracy ±1um

22. Air-drying area: gas nozzle + solution precipitation recovery device

23. Bellows length: 8 meters, the whole machine is 12 meters

24. Feeding method: Compressed nitrogen feeds the slurry into the feed box. The feed flow adjustment adopts a motor with ball screw and guide rail fitting structure. The feed flow is adjusted with high precision. After use, there is no need to clean the equipment. Replace 1 Pipeline is enough;

25. Power and distribution: bottom plate heating 300 width, power 4.2KW, servo motor power: 1.5KWW fan: 250W total power: 6.5KW

FeaturesØ 10 inch color touch screen, man-machine friendly interface. Using Siemens PLC control, stable performance, high precision, in line with industrial automation control standards;

Ø Exhaust air circulation system, uniform exhaust, variable frequency speed control of flow;

Ø High precision scraper, digital dial indicator display, resolution um;

Ø Adopt high-precision servo motor to control the speed of the steel belt, and the speed range can reach 0.05-10M/min;

Ø Automatic liquid level control, PID automatic adjustment, precision control ±0.5mm;

Unique and convenient process1. The air intake adopts high-density filter to achieve dust-free space;

2. Transparent tempered glass window, convenient to watch the internal casting status;

3. The thickened aluminum alloy is used for the internal materials of the spray-painted accessories to ensure the practical life of the accessories;

4. The whole machine adopts high-strength aluminum alloy frame, and the panel uses 2mm aluminum alloy plate, which is durable and beautiful.

Main configuration

1. Casting head 1 set

2. Cleaning device 1 set

3. Bellows 8 meters

4. Conveyor belt 1 group

5. Automatic feeding 1 set

Slit head

Slit head